Muaj zog Tungsten Carbide Cold Heading Tuag rau Bolt Cold Heading Forging Tuag

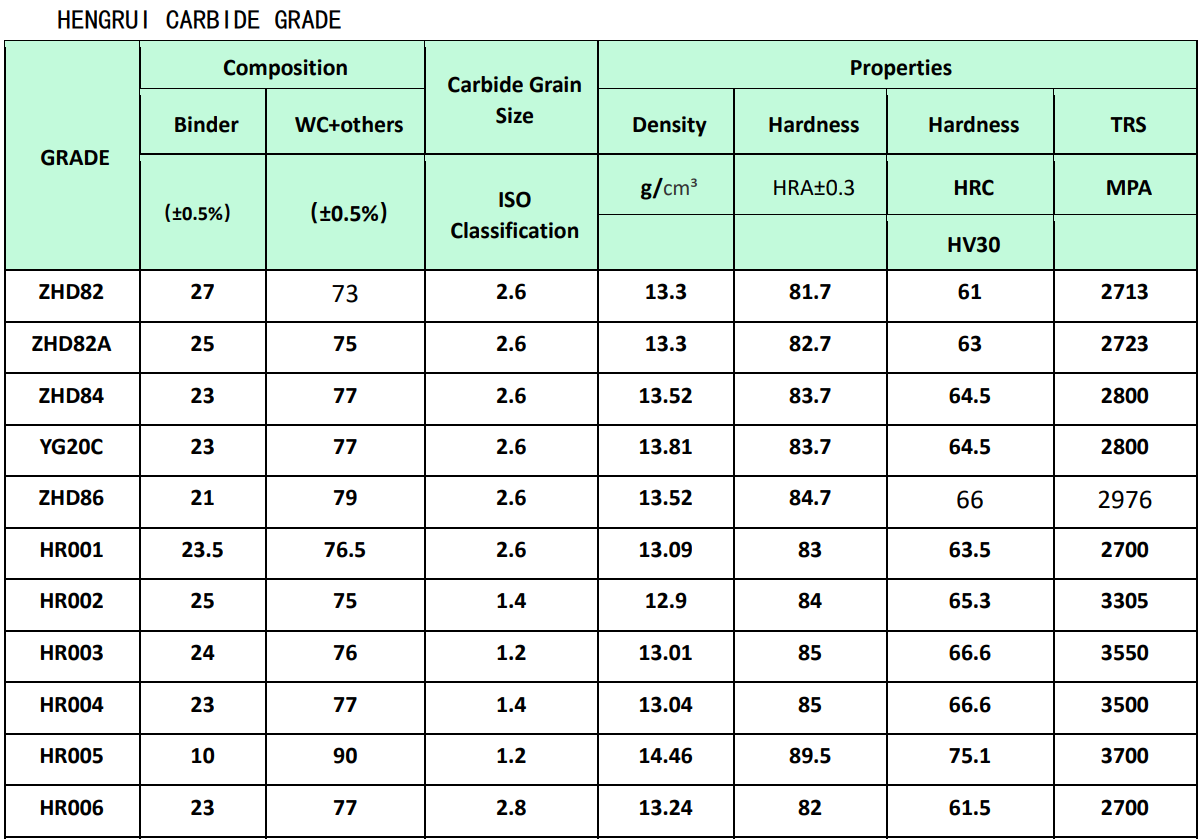

Peb lub Hoobkas muaj cov cuab yeej ua tiav thiab muaj zog ntau lawm tshuab.Piv txwv li, peb muaj kev koom tes ntev nrog qee lub tsev R & D los tsim thiab tsim cov khoom tshiab hauv kev lag luamcemented carbide.Peb tau pab R&D cov chav nyob kov yeej thiab daws tau ntau yam teeb meem kev lag luam thiab tau txais kev ntseeg siab thiab kev lees paub ntawm R&D units.

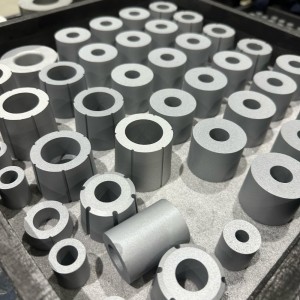

Lub Hoobkas muaj kev ua haujlwm zoo thiab kev sim, thiab tuaj yeem muab ntau yam khoom zoo thiab kev pabcuam rau cov neeg siv khoom hauv tsev thiab txawv teb chaws raws sijhawm, thiab tuaj yeem tsim, txheej txheem thiab tsim ntau yam khoom siv cemented carbide thiab pwm raws li qhov sib txawv ntawm cov neeg siv khoom. .Ntau cov neeg siv hauv tsev thiab txawv teb chaws tuaj yeem txais tos los tsim kev lag luam kev sib cuag thiab kev koom tes nrog Renqiu Hengrui Cemented Carbide Co., Ltd.

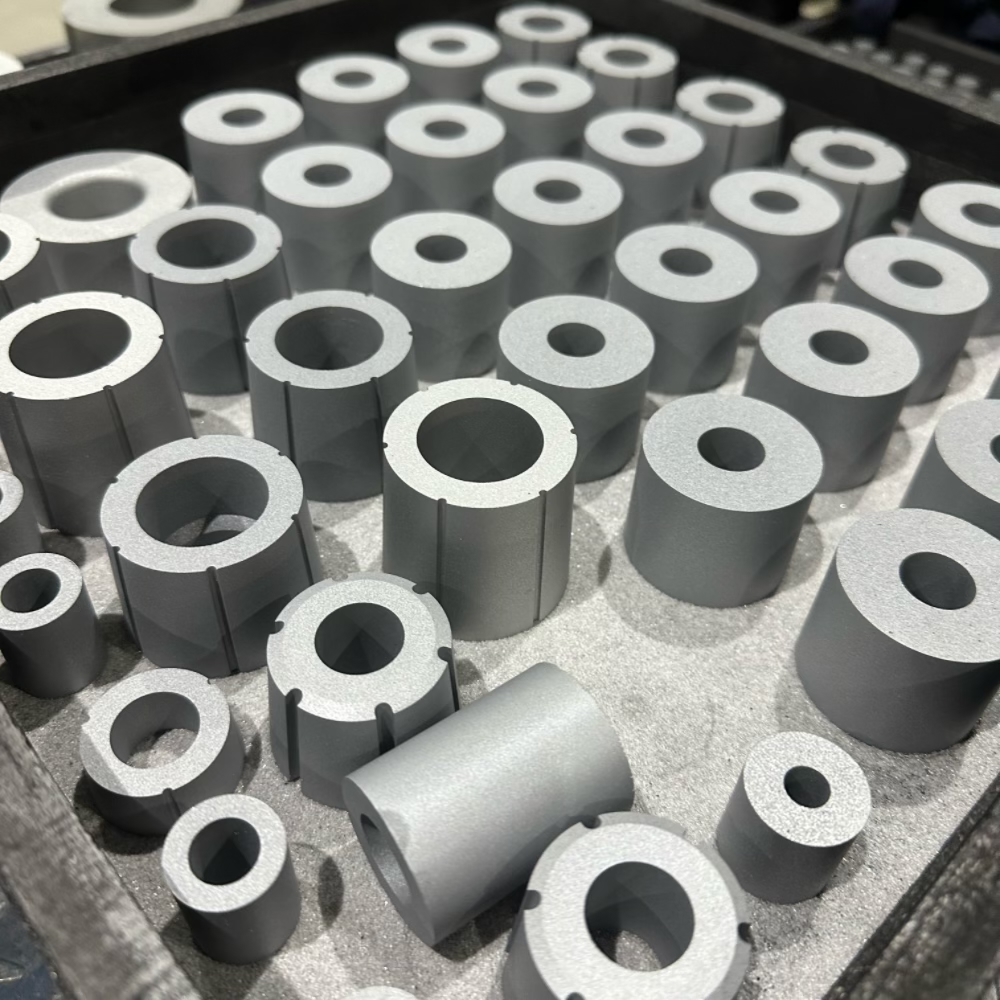

Cov khoom sib txuam → ntub pob zeb → Sib xyaw WC thiab Cobalt Fais Fab → Nias → HIP Sintering Rauv → QC Nthuav → Ntim

Lub thermal ua haujlwm zoo ntawm cov pwm muaj kev cuam tshuam zoo rau kev ua haujlwm thiab kev pabcuam lub neej ntawm pwm.Nws tuaj yeem pom los ntawm kev txheeb xyuas thiab kev txheeb xyuas ntawm qhov ua rau pwm tsis ua haujlwm uas pwm tsis ua haujlwm "kev sib tsoo" tshwm sim los ntawm kev kho cua sov tsis zoo rau ntau tshaj 40%.Lub quenching deformation thiab tawg ntawm qhov chaw ua haujlwm ntawm cov pwm thiab qhov tawg thaum ntxov thaum siv yog txhua yam cuam tshuam nrog cov txheej txheem thermal ua ntawm pwm.Forging txheej txheem, npaj kev kho cua sov, quenching thiab tempering, kev nyuaj siab annealing, machined nto zoo, thiab lwm yam.

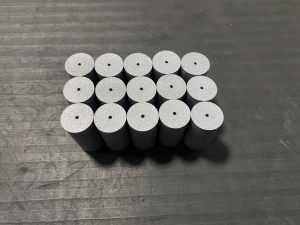

Peb muab kev ua haujlwm nrog cov khoom siv, kev pabcuam customized, kev tsim cov duab kos, thiab tuaj yeem tsim pwm tsim rau koj siv raws li koj lub tshuab txias taub hau.

Peb muaj 5 HIP sintering rauv nrog cov zis txhua hnub ntawm 1.2 tons.Kev xa khoom siv sijhawm 3 mus rau 10 hnub tom qab them nyiaj.