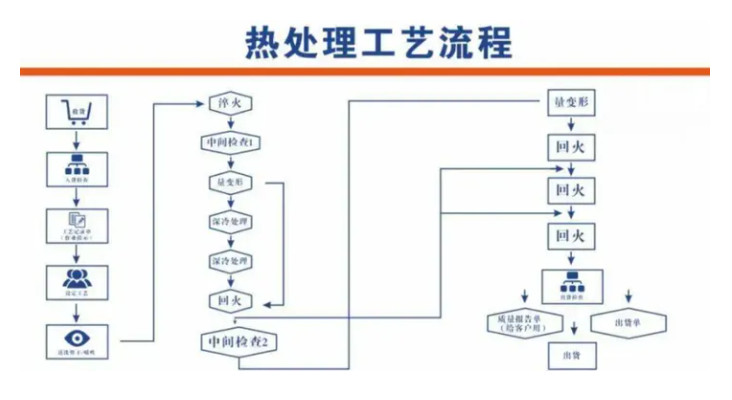

Kev kho cua sov txheej txheem ntawmcemented carbideworkpieces muaj xws li cov kauj ruam ntawm: cua sov lubcemented carbideworkpieces rau 500 ° C mus rau 1300 ° C los ntawm induction cua sov, thiab ces txias.Cov txheej txheem kev kho cua sov muab los ntawm kev tsim khoom tsis tas yuav tsum tau khaws cov cua sov, yog qhov yooj yim, luv luv hauv lub sijhawm, thiab muaj txiaj ntsig zoo, thiab tuaj yeem txhawb nqa kev siv dav hauv kev kho cua sov hauv cemented carbide.Kev kho cua sov yog hais txog cov txheej txheem hlau alloy thermal ua haujlwm uas cov khoom siv nyob rau hauv lub xeev ruaj khov thiab tau txais los ntawm cua sov, tuav thiab txias kom tau txais cov qauv tsim thiab cov khoom.

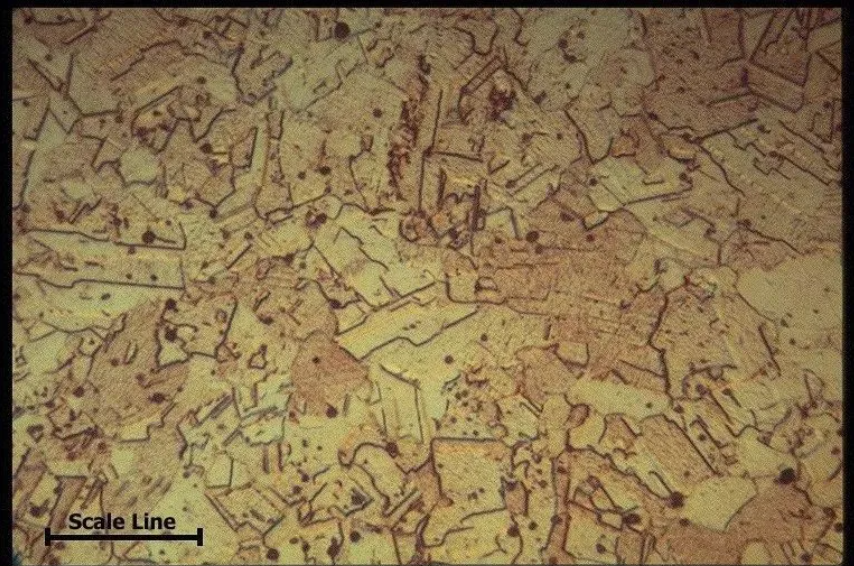

Piv txwv li, peb feem ntau siv cov txheej txheem quenching thiab tempering (ob chav kho cua sov, quenching thiab tempering).Ntawd yog, tom qab quenching, nws raug rau kev kub siab tempering.Xws li 45 steel, 30CrMOV9,tungsten- npib tsib xee alloy,tungsten carbide alloythiab lwm yam khoom siv hlau, qhov siab dua cov ntsiab lus carbon, qhov siab dua qhov hardness tom qab kev kho cua sov.

Post lub sij hawm: Mar-12-2024