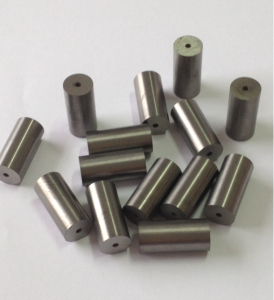

High quality YG15 Cov menyuam 3D Tungsten carbide yob rau txias dov rebars

1. Suav Hoobkas tshwj xeeb hauv kev ua thiab ntau lawm, ISO certification.

2. Ntau qhov ntau thiab tsawg thiab hom muaj rau OEM.

3. Ua los ntawm 100% thawj cov ntaub ntawv zoo

4. Pab neeg tsim khoom, kev xa khoom sai

5. Kev pab cuam tom qab muag dawb thiab kev txhawb nqa

Carbide cov menyuam siv rau ntawm qhov ncab txo zeb rau cov tuav, xov steel tuav thiab cov hlau uas muaj cov kav ntev 10 mus rau 20 npaug siab dua piv rau cov menyuam yaus.Qhov zoo ntawm qhov chaw thiab cov steel bar loj qhov tseeb tau zoo heev.Cov cemented carbide cov menyuam txo cov nqi tsim khoom thiab txhim kho qhov zoo.Cov menyuam yaus rau Profile Hlau Rolling, Flat Hlau Rolling, Kev Tsim Kho Hlau Rolling, Plain Hlau Rolling thiab Vuam Hlau Rolling, Hlau Ncaj, Hlau Tawv thiab lwm yam.

| Qib | Qhov ntom | TRS | Hardness | Kev ua tau zoo & Daim ntawv thov pom zoo |

| g/cm3 | MPa | HRA | ||

| YG 6 | 14.9 Nws | 2100 | 90 | los yog coring crowns, hluav taws xob thee laum khoom, thee txiav picks, roj cone khoom thiab scraping riam, usd nyob rau hauv geological prospecting, thee mining thiab roj zoo tho txawv. |

| YG 8 | 14.7 ib | 2400 | 89.5 ua | Rau coring crowns, hluav taws xob thee laum khoom, thee txiav picks, cone laum khoom thiab scraping riam khoom, siv nyob rau hauv geological prospecting, thee mining thiab roj zoo tho txawv. |

| YG8C | 14.7 ib | 2450 | 88.5 ib | Feem ntau yog siv los ua cov nyees khawm ntawm cov khoom me me thiab nruab nrab ntawm cov khoom siv percussion thiab raws li cov khoom siv los ntawm cov khoom siv los txiav cov mos thiab nruab nrab nyuaj formations. |

| YG9C | 14.6 ib | 2450 | 87.8 ua | Haum rau strips, conical nyees khawm rau teb percussion-resistant, geological prospecting nyees khawm, txiav mos thiab nruab nrab nyuaj formations. |

| YG10C | 14.4 ib | 2550 | 87 | Feem ntau rau cov nyees khawm thiab cov ntxig ntawm cov khoom siv teb rau kev txiav cov nruab nrab-nyuaj thiab nyuaj formations. |

| YG11C | 14.4 ib | 2600 | 87 | Feem ntau rau cov inserts thiab nyees khawm ntawm percussion khoom thiab tricone khoom los txiav nruab nrab-nyuaj, nyuaj, thiab heev formations. |

| YG13C | 14.2 | 2650 | 86.5 ib | Feem ntau yog rau cov nyees khawm ntawm tricone cov khoom thiab cov khoom ntxig ntawm cov khoom siv teb rau kev txiav nyuaj thiab vey nyuaj formations. |

| YG 15 C | 14 | 2700 ib | 86.5 ib | Rau roj lub khob laum khoom, rau nruab nrab mos thiab nruab nrab - tawv pob zeb. |

| YG 15 | 14 | 2500 | 87.5 ib | Lub zog zoo thiab tsis hnav tsis kam, rau cov khoom siv rauj pob zeb xyaum thiab cov pob zeb hnyav, rau cov pob zeb nyuaj thiab nyuaj heev. |

Cov khoom sib txuam → ntub pob zeb → Sib xyaw WC thiab Cobalt Fais Fab → Nias → HIP Sintering Rauv → QC Nthuav → Ntim

Tungsten Carbide Roller yog ib yam khoom siv hlau uas muaj tungsten carbide thiab cobalt nrog siab hardness thiab hnav tsis kam.Muaj cov zoo tagnrho rau siv nyob rau hauv daim ntawv thov qhov twg lub zog, durability thiab ntev lub neej yog yam tseem ceeb.Qhov kev ua tau zoo ntawm cov tungsten carbide cov menyuam muaj feem xyuam rau cov ntsiab lus ntawm kev sib txuas ntawm cov hlau thiab qhov loj ntawm matrix theem-tungsten carbide hmoov particle.Cov ntsiab lus sib txawv ntawm cov binder thiab cov sib thooj tungsten carbide particle loj daim ntawv sib txawv carbide qib.Yog hais tias cov ntsiab lus ntawm cov hlau binder yog nce los yog particle loj ntawm tungsten carbide yog nce, lub hardness ntawm cov cemented carbide txo thiab toughness nce.Tungsten Carbide (WC) yog ob zaug muaj zog li hlau thiab zoo ib yam li corundum hauv hardness.Tungsten carbide rollers sib xyaw ua ke zoo tshaj plaws nrog kev ua haujlwm tsis zoo thiab hnav thiab lawv muaj nyob rau hauv ntau qhov ntau thiab tsawg.Lawv tuaj yeem raug milled raws li cov neeg siv khoom tshwj xeeb.Nws muaj qhov zoo ntawm kev hnav tsis kam, lub neej ntev thiab kev ua haujlwm siab thaum lub sijhawm kub ceev dov.

1. Siv 100% tungsten carbide raw khoom.

2. Cov khoom siv tshuaj ruaj khov

3. Kev ua tau zoo heev thiab zoo hnav / corrosion kuj

4. HIP sintering, zoo compactness

5. Ncua tseg, siab machining raug/precision

6. OEM customized ntau thiab tsawg muaj

7. Lub Hoobkas muaj

8. Kev soj ntsuam xyuas cov khoom zoo

1. Peb yuav sim peb qhov zoo tshaj plaws los teb peb cov neeg siv khoom thov tsis pub dhau 24 teev.

2. Peb yuav muaj kev sib txuas lus zoo thiab muaj txiaj ntsig nrog peb cov neeg siv khoom.

3. Peb muab kev tswj hwm zoo hauv chav kawm thawj zaug thiab kev pab cuam tom qab muag.

Peb yuav xa cov khoom thauj loj hauv 30 hnub tom qab them nyiaj, thaum, Yog tias muaj kev thov soecific ntawm lub sijhawm khoom xa tuaj.Peb tuaj yeem hloov pauv raws li cov neeg siv khoom thov, yog li lub sijhawm xa khoom luv luv yog muaj tiag.