Fastener Kev Lag Luam Siv Tungsten Carbide Txias Forging Tuag

1. Suav Hoobkas tshwj xeeb hauv kev ua thiab ntau lawm, ISO certification.

2. Ntau qhov ntau thiab tsawg thiab hom muaj rau OEM.

3. Ua los ntawm 100% thawj cov ntaub ntawv zoo

4. Pab neeg tsim khoom, kev xa khoom sai

5. Kev pab cuam tom qab muag dawb thiab kev txhawb nqa

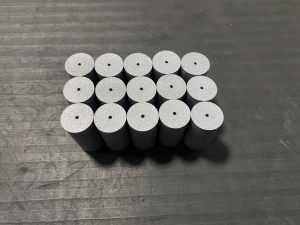

Tungsten carbide txias taub hau tuag yog dav siv los ua tiav tuag casting pwm, punch tuag, hlau kos tuag, tshuab pwm, kev tuag tuag, extrusion tuag, xovxwm pwm, pwm qhov chaw, trimming tuag, txias hau tuag, forging pwm, txias sib sau tuag lwm.

| Tungsten Carbide Txias Forging / taub hau tuag | |||||

| Qib | Qhov ntom | TRS | Hardness | Kev ua tau zoo & daim ntawv thov pom zoo | |

| g/cm³ | MPa | HRA | |||

| YG 11 | 14.4 ib | ≥3000 | 88.5 ib | Kev tsim lossis stamping tuag rau cov hmoov hlau thiab cov hmoov tsis yog hlau. | |

| YG 15 | 14 | ≥3400 | 87.5 ib | Rau fabricating kos duab tuag ntawm steel hlab thiab rods nyob rau hauv siab compressibility piv;xuas nrig ntaus, stamping, forging cov cuab yeej nyob rau hauv kev ntxhov siab loj. | |

| YG 20 | 13.5 Nws | ≥3800 | 85.5 ua | Rau fabricating ntawm stamping tuag rau saib qhov chaw, caij nplooj ntoos hlav daim hlau ntawm cov twj paj nruag, roj teeb hub, me me steel pob, screws, ntsia hlau hau. | |

| YG 15 C | 14 | ≥4000 | 86.5 ib | Rau cov roj pob zeb laum khoom, txiav cov pob zeb nruab nrab thiab tawv tawv; debarking thiab txiav cov ntoo khov, cov ntoo mos thiab cov ntoo qub. | |

| YG16C | 13.9 Nws | ≥3500 | 85.5 ua | Impact resistance forging tuag. | |

| YG18C | 13.7 ib | ≥3600 | 84.5 ib | Kev cuam tshuam tsis kam forging tuag, kub xovxwm forging tuag thiab rollers. | |

| YG20C | 13.5 Nws | ≥3800 | 83.5 ib | Tuag rau hnav resistant los yog tej yam resistant daim ntawv thov. | |

| YG22C | 13.3 | ≥4000 | 83 | Txiv ntseej sib sau tuag thiab muaj kev cuam tshuam zoo rau forging tuag. | |

| YG 25 C | 13.1 | ≥4250 | 82.5 ib | Stainless bolt header tuag thiab rollers. | |

Cov khoom sib txuam → ntub pob zeb → Sib xyaw WC thiab Cobalt Fais Fab → Nias → HIP Sintering Rauv → QC Nthuav → Ntim

| Hom | OD | ID | H | Ua siab ntev | ||

| OD | Id | H | ||||

| φ10 ~ 14 × φd | 10 ~ 14 | 1.0 ~ 5.0 | 15-40 | D × + 3% | d × -3% | H × 3% |

| φ15 ~ 24 × φd | 15-24 : kuv | 1.5-8.0 Nws | 20-60 | |||

| φ25 ~ 40 × φd | 25-40 Nws | 1.5 ~ 25 | 30-60 | |||

| φ42 ~ 95 × φd | 42-95 : kuv | 2.0 ~ 50 | 20 x95 | |||

Rau lwm qhov ntau thiab tsawg peb tuaj yeem ua raws li cov neeg siv khoom xav tau lossis kos duab.

1. Peb yuav sim peb qhov zoo tshaj plaws los teb peb cov neeg siv khoom thov tsis pub dhau 24 teev.

2. Peb yuav muaj kev sib txuas lus zoo thiab muaj txiaj ntsig nrog peb cov neeg siv khoom.

3. Peb muab kev tswj hwm zoo hauv chav kawm thawj zaug thiab kev pab cuam tom qab muag.

Peb yuav xa cov khoom thauj loj hauv 30 hnub tom qab them nyiaj, thaum, Yog tias muaj kev thov soecific ntawm lub sijhawm khoom xa tuaj.Peb tuaj yeem hloov pauv raws li cov neeg siv khoom thov, yog li lub sijhawm xa khoom luv luv yog muaj tiag.

Feem ntau 30% T / T ua ntej, tshuav 70% ua ntej xa khoom.Kuj tseem tuaj yeem hloov pauv raws li cov neeg siv khoom thov.

Peb tsim cov khoom sib txawv ntawm cov duab thiab qhov ntau thiab tsawg kom haum rau peb cov neeg siv khoom raws nraim, txawm tias lawv xav tau cov blocks lossis nplooj ntawv, lub tog raj kheej, bearings, cov lus qhia lossis cov hniav.